| Model | DXD-2 | DXD-3 | DXD-4 | DXD-5 | DXD-6 | DXD-7 | DXD-8 | DXD-9 | DXD-10 |

| Cooling Capacity* (kW) | 8 | 13 | 18 | 22 | 30 | 40 | 45 | 55 | 65 |

| Rated Flow (L/min) | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Max.Working Pressure (bar) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Fan Power (W) | 150 | 200 | 200 | 2*150 | 2*150 | 2*150 | 2*200 | 4*200 | 4*200 |

| Working Voltage (V) | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Inlet&Outlet Thread | G1¾'' | G1 '' | G1¼'' | G1¼'' | G1¼'' | G1¼'' | G1½'' | G1½'' | G1½'' |

| Thermometric Thread | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' |

| Noise Level** (dB) | 52 | 68 | 71 | 72 | 74 | 75 | 78 | 79 | 84 |

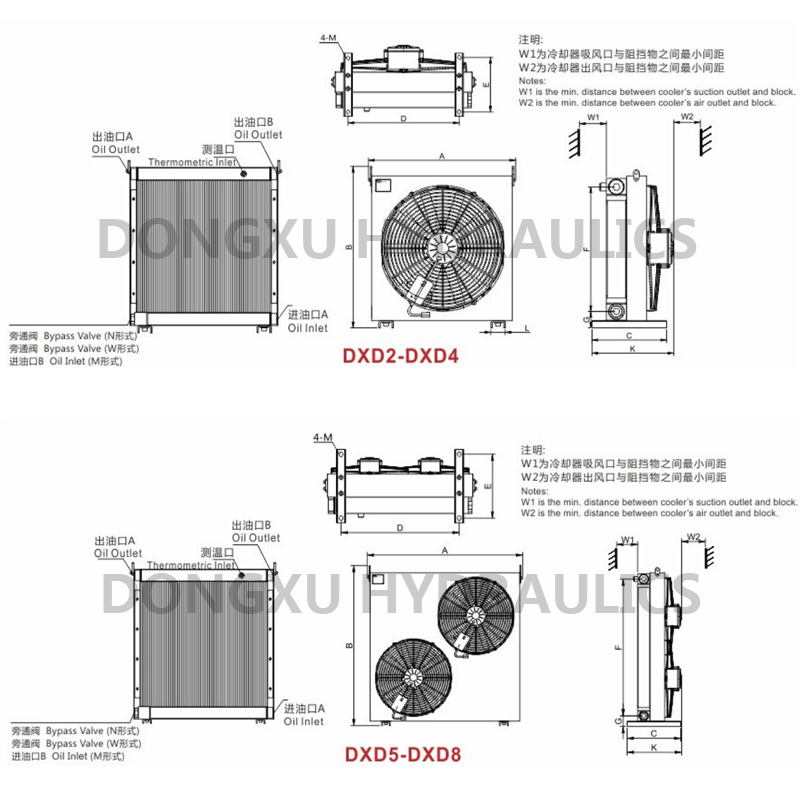

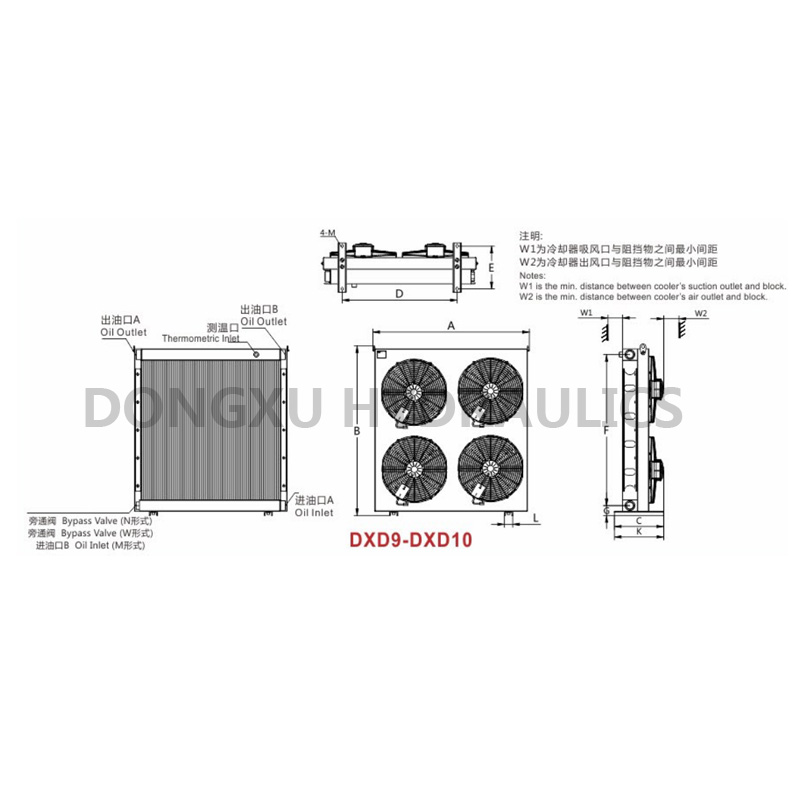

| A (mm±5) | 365 | 425 | 530 | 585 | 630 | 630 | 750 | 835 | 970 |

| B (mm±5) | 400 | 500 | 565 | 600 | 625 | 625 | 765 | 920 | 1060 |

| C (mm±2) | 250 | 250 | 260 | 300 | 300 | 330 | 400 | 400 | 400 |

| D (mm±2) | 230 | 290 | 390 | 450 | 490 | 490 | 560 | 645 | 700 |

| E (mm±2) | 210 | 210 | 220 | 260 | 260 | 280 | 350 | 350 | 350 |

| F (mm±5) | 295 | 384 | 434 | 475 | 495 | 495 | 634 | 780 | 920 |

| G (mm±5) | 45 | 50 | 55 | 55 | 55 | 55 | 55 | 60 | 60 |

| K (mm±10) | 240 | 280 | 310 | 330 | 330 | 350 | 390 | 465 | 380 |

| L (mm±2) | 40 | 40 | 40 | 40 | 45 | 45 | 45 | 50 | 50 |

| M (mm±2) | 12*18 | 12*18 | 12*18 | 12*18 | 14*22 | 14*22 | 14*22 | 14*22 | 14*22 |

| W1 | 180 | 200 | 250 | 300 | 300 | 300 | 350 | 400 | 450 |

| W2 | 360 | 400 | 500 | 600 | 600 | 700 | 800 | 900 | 1000 |

| Note: * Cooling capacity: cooling power at △T=40℃. ** The noise value is measured at a distance of 1m from the cooler, which is only for reference. Because it is affected by the surrounding environment, medium viscosity and reflection. *** This table only takes AC380V-50HZ as an example. **** Motor power protection level: IP44; Insulation class: F; CE standard. (Other options please contact DONGXU) | |||||||||

Agriculture

Machine tools

| DXD | 8 | A2 | N | C | X | O | O |

| Cooler Type: Integral DC Condenser Fan Series | Plate Size: 2/3/4/5/6/7/8/9/10 | Voltage: A2=DC24V⬅Standard A1=DC12V | Bypass Valve: N=Build-in⬅Standard W=External M=Without Bypass Valve | Oil Hole Direction: C=Side in side out⬅Standard S=Up in up out | Wind Direction: X=Suction⬅Standard C=Blowing | Temp. Controller: O=Without controller⬅Standard Z=Integrated self-protected temperature control switch C=Temp. Transmitter-- C1=Compact,C2=Digital | Heatsink Protection: O=Without protection⬅Standard S=Anti-Stone net C=Dust net |

Walking machine

Hydraulic system circuit, independent cooling circuit and lubricating oil cooling system. For examples, walking machinery, machine tool machinery, agricultural machinery, engineering vehicles, construction machinery, and so on.

Construction

Engineering

1. The cooler must be placed in a well-ventilated place, and it is easy to deal with the dirt on the air inlet side. There must be a space (above the radius of the wind blade) before and after to facilitate air circulation and good heat exchange effect. 2. In order to protect the cooler from rupture, when the cooler is installed in the oil return circuit, a bypass unloading circuit must be installed in parallel with the cooler, and when the pressure relief encounters a convex wave, it can be opened and unloaded preferentially. 3. For correct installation, it is recommended to use a hose, properly install a bypass unloading circuit, or use an independent circulating cooling method. 4. For the cleaning of the air side, compressed air or hot water can be used to remove it along the direction of the aluminum sheet. Please pay attention to the power off during cleaning, and protect the fan coil from entering water.